Samsung BESPOKE 5.3 Cu. Ft. High-Efficiency Stackable Smart Front Load Washer with Steam and Super Speed Wash Brushed Black WF53BB8700AVUS - Best Buy

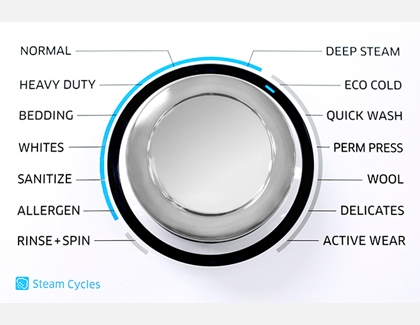

Samsung 27" 4.1 Cu. Ft. Top Loading Washer with 8 Wash Programs, 3 Wash Options & Self Clean - White | P.C. Richard & Son

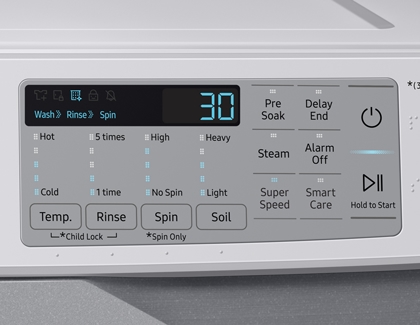

Samsung 27 in. 4.5 cu. ft. Smart Stackable Front Load Washer with 10 Wash Programs, 6 Wash Options & Self Clean - White | P.C. Richard & Son